Have you ever wondered to have an extra hand that will do all of your work? Have you ever ask yourself how all the machines do all the work, from assembling parts to packaging products in a factory? And what is the main purpose of a robotic arm in industrial automation?

Nowadays, the technology is so advanced that all of the work of a factory worker can be done with the help of industrial automation with more efficiency. How? Well, robotic arms are the backbone of modern-day manufacturing and industrial automation. They don’t just work faster; they work smarter, making complex processes more efficient.

Henry Ford once said, “Coming together is a beginning; keeping together is progress; working together is success.” And robotic arms are perfect partners in this industrial automation journey.

Even if you may have seen and heard about robots in movies and tech news but understanding their real-world applications can be overwhelming. Don’t worry—I’m here to help you. In this article, we’ll dive into the world of robotic arms, breaking down their purpose and importance of them in modern industries. By the end of this article, you’ll see how they truly revolutionize the way automation industry work.

Table of Contents

Industrial Automation

When you think of the future of a factory workplace, what comes to your mind? For me, there are machines working 24 hours day tirelessly to produce the goods we use every day. This is industrial automation—a technological revolution where machines take over repetitive and dangerous tasks of human. So that we can give our time on more complex problems and be more creative. That’s industrial automation in a nutshell.

From car manufacturing to food packaging, automation is revolutionizing how we make our things. Industrial automation is about doing things differently, faster, and better.

What is Robotic Arm?

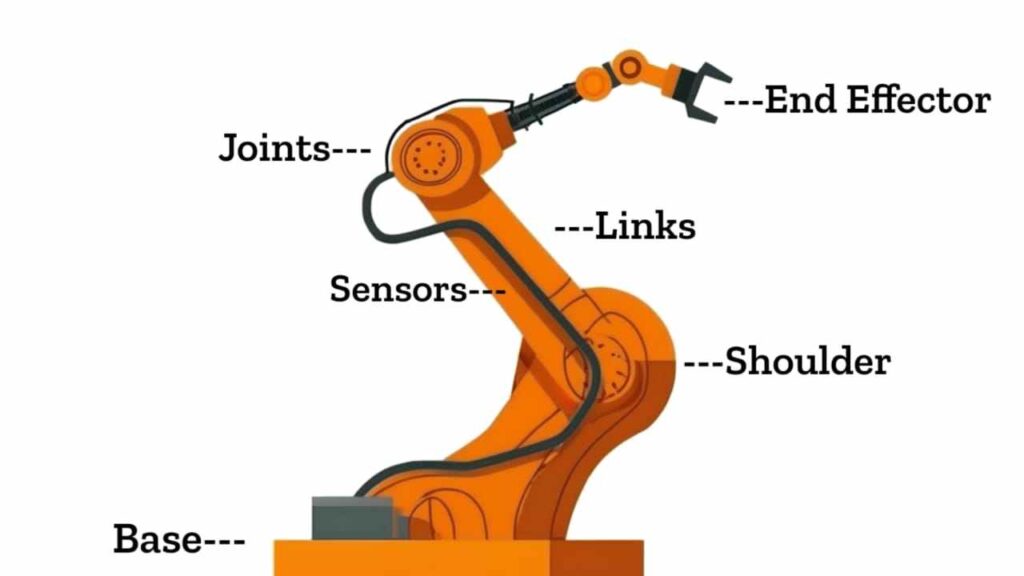

A robotic arm is a versatile machine designed work like a human arm. They are equipped with joints, actuators and sensors, allowing them to move in multiple directions and perform various tasks. Just like a human arm, it can rotate, extend, and grab.

Parts of Robotic Arm

Let’s break down the key parts of a robotic arm, which are like the bones and muscles of this mechanical arm:

| Robotic Arm Part | Description |

|---|---|

| Base | The stable foundation that supports the entire arm structure. |

| Joints | Connects segments, enabling movement and rotation. |

| Links | The rigid section between joints, similar to our bones. |

| End Effector | The “hand” of the arm, designed to interact with objects—whether gripping, welding, or assembling. |

| Actuators | The “muscles” that drive the arm’s movements, typically driven by motors.. |

| Sensors | Providing “sight” and “touch,” they ensure precision and accuracy. |

Steve Jobs once said, “Design is not just what it looks like and feels like. Design is how it works.” Every part of a robotic arm is designed with a purpose.

What is the main purpose of a Robotic Arm in Industrial Automation?

As I said previously, robotic arm is the backbone of automation industry. Why? because it performs all the tasks that once required human hands but with far more precision, speed and consistency. Let’s break down what is the main purpose of a robotic arm in industrial automation:

Efficiency of Robotic Arm

Let’s say you have to assemble thousands of small components by hand. How would you do that? There is no doubt that it is time consuming and you can make a mistake during this time. Robotic Arm can perform repetitive tasks again and again at lightning speed, considering each and every movement looks identical.

Safety by Robotic Arm

In my experience, one of the most useful advantages of robotic arms is how they increase human safety on dangerous tasks. Robots protect human workers, keeping them out of dangerous situation.

Consistency of Robotic Arm

Imagine having a worker in your factory who never gets tired, distracted, or makes a mistake. A robotic arm can help you there. It can work for you day and night, 24 hours a day, 7 days a week, and even 365 days a year without getting tired. What does that mean is your business is always running. Where you can use this manpower in other creative fields.

Speed of Robotic Arm

Speed is a key factor in the game of manufacturing. A robotic arm is always move faster than a human. Whether it’s assembling parts, welding, or packaging, the arm’s speed can be precisely programmed to match the demands of the production line.

Cost-Effectiveness of Robotic Arm

Initially, the investment in robotic arms might seem expensive. But over time, they save money by reducing labour costs, minimising errors, and increasing production speed. It’s like planting a tree; it takes time to grow, but once it does, it saves much money you can’t even imagine.

Uses of Robotic Arm

Robotics arm is a versatile tool in the field of Industrial Automation. It has revolutionized the way of how tasks are performed in factories and beyond. Here are some uses of it in different industries:

- Assembly Line

- Welding

- Material Handling

- Packaging

- Medical Applications

These are just a few examples of how robotic arms are revolutionizing different industries. Their ability to handle complex and repetitive tasks opens up new possibilities for innovation and efficiency in various sectors. How do you think robotic arms might impact your field?

Conclusion

In conclusion, robotic arms are game-changers in industrial automation. The question “What is the main purpose of a Robotic Arm in Industrial Automation?” can be answered simply: it’s about precision, efficiency, and consistency. As technology advances, these robotic arms will integrate more to our industries, offering greater safety and capabilities. In industrial automation, robots are not just tools; they are partners in productivity